- Use the control bar or mouse to view the 360-degree image.

- Select the markers for information about each system.

-

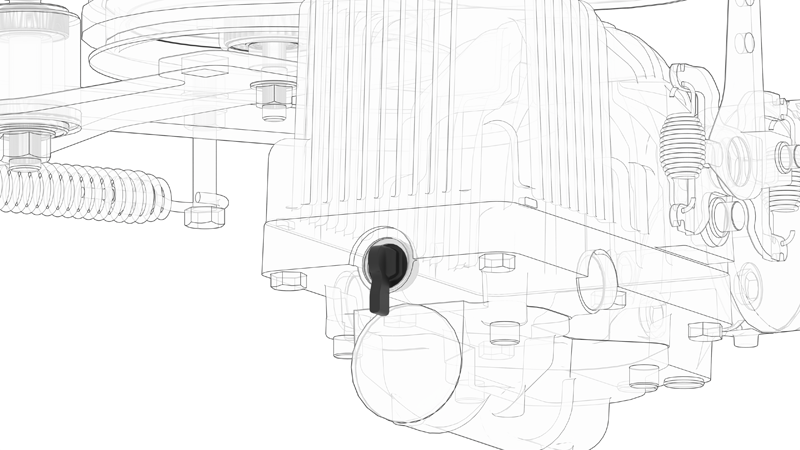

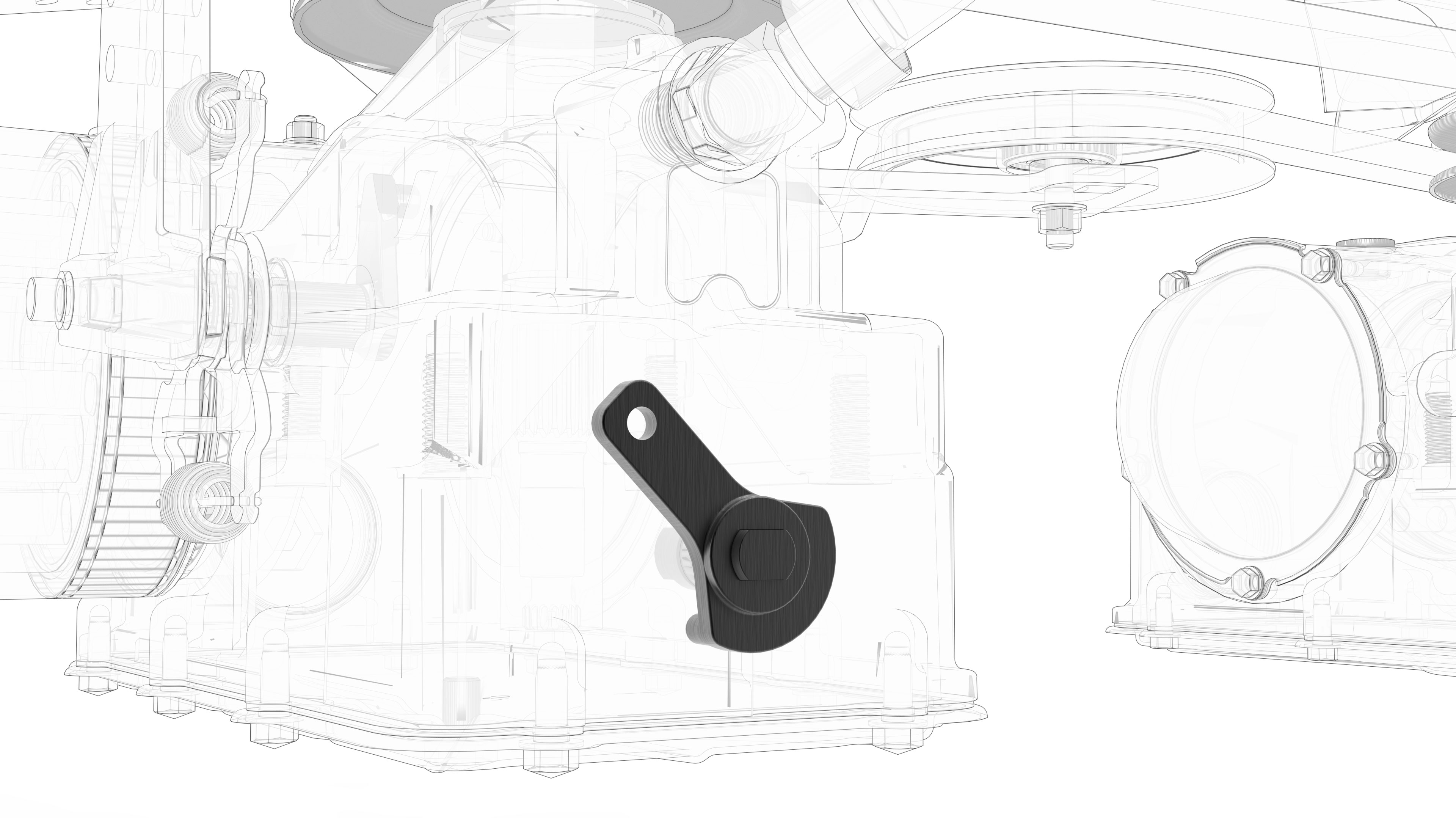

Dump Valve

Each Parker HTJ hydrostatic transaxle has a dump valve, which is located on the front

side of the transaxle and is easily accessible in the front of each rear wheel. When

the dump valve is released, it will allow the operator to easily freewheel the Zero-Turn.

-

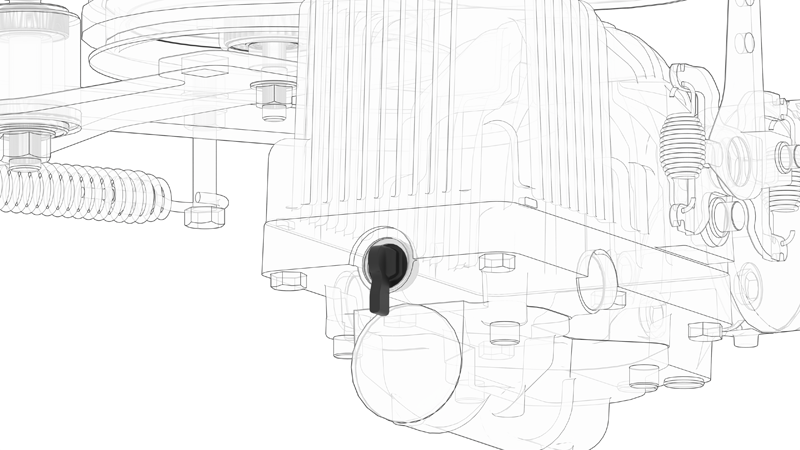

Dump Valve

Each Parker HTJ hydrostatic transaxle has a dump valve, which is located on the front

side of the transaxle and is easily accessible in the front of each rear wheel. When

the dump valve is released, it will allow the operator to easily freewheel the Zero-Turn.

-

Filter

The oil filter is located on the rear side of the HTJ hydrostatic transaxle and is easily

accessible with the unit installed in the Zero-Turn. The oil filter is expected to be

replaced during each oil change. The break-in oil period is at 300 hours and every 1,000 hours

thereafter if Parker HT-1000™ Oil is used.

Oil filters will be available in the Oil Service Kit (70731700).

Further Information

-

Filter

The oil filter is located on the rear side of the HTJ hydrostatic transaxle and is easily

accessible with the unit installed in the Zero-Turn. The oil filter is expected to be

replaced during each oil change. The break-in oil period is at 300 hours and every 1,000 hours

thereafter if Parker HT-1000™ Oil is used.

Oil filters will be available in the Oil Service Kit (70731700).

Further Information

-

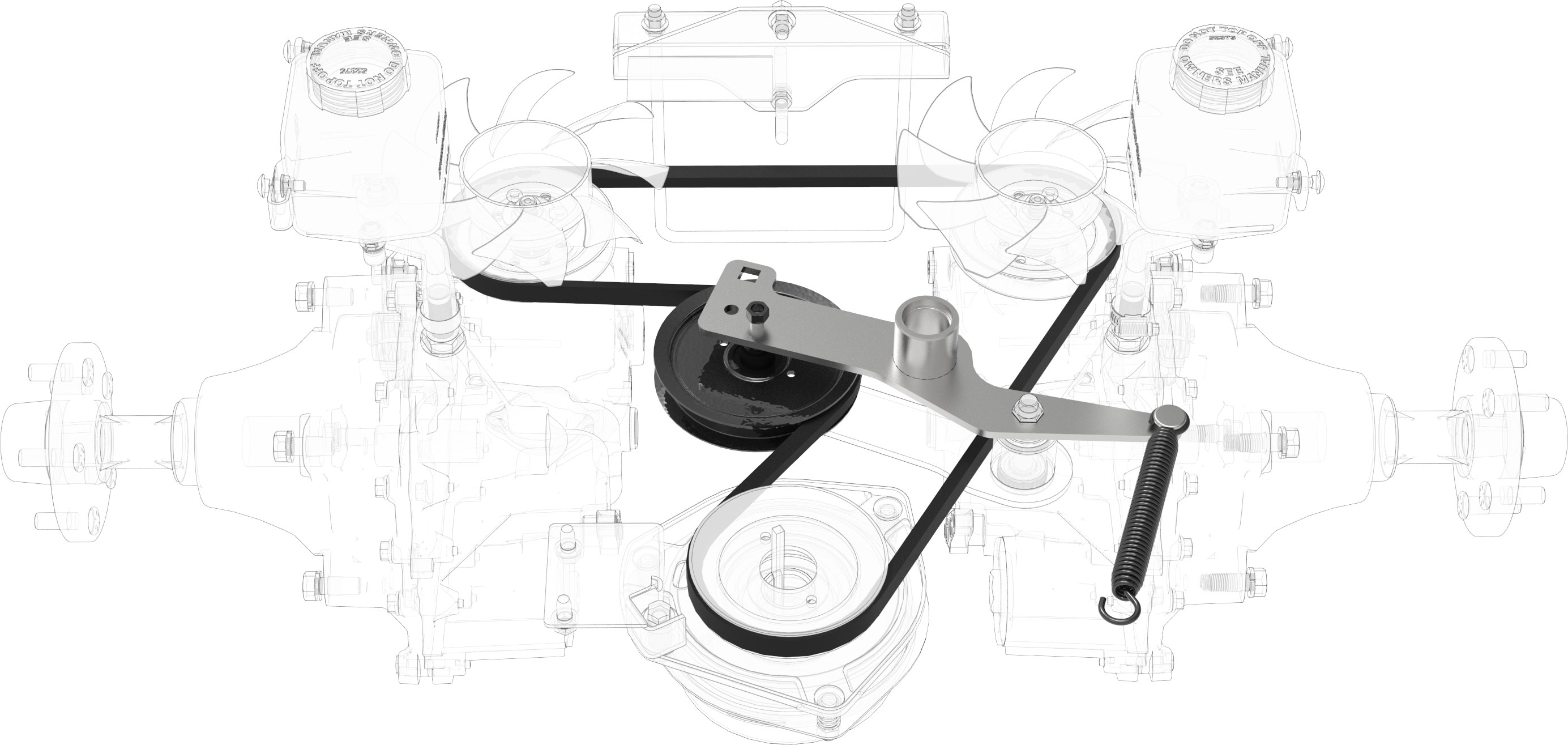

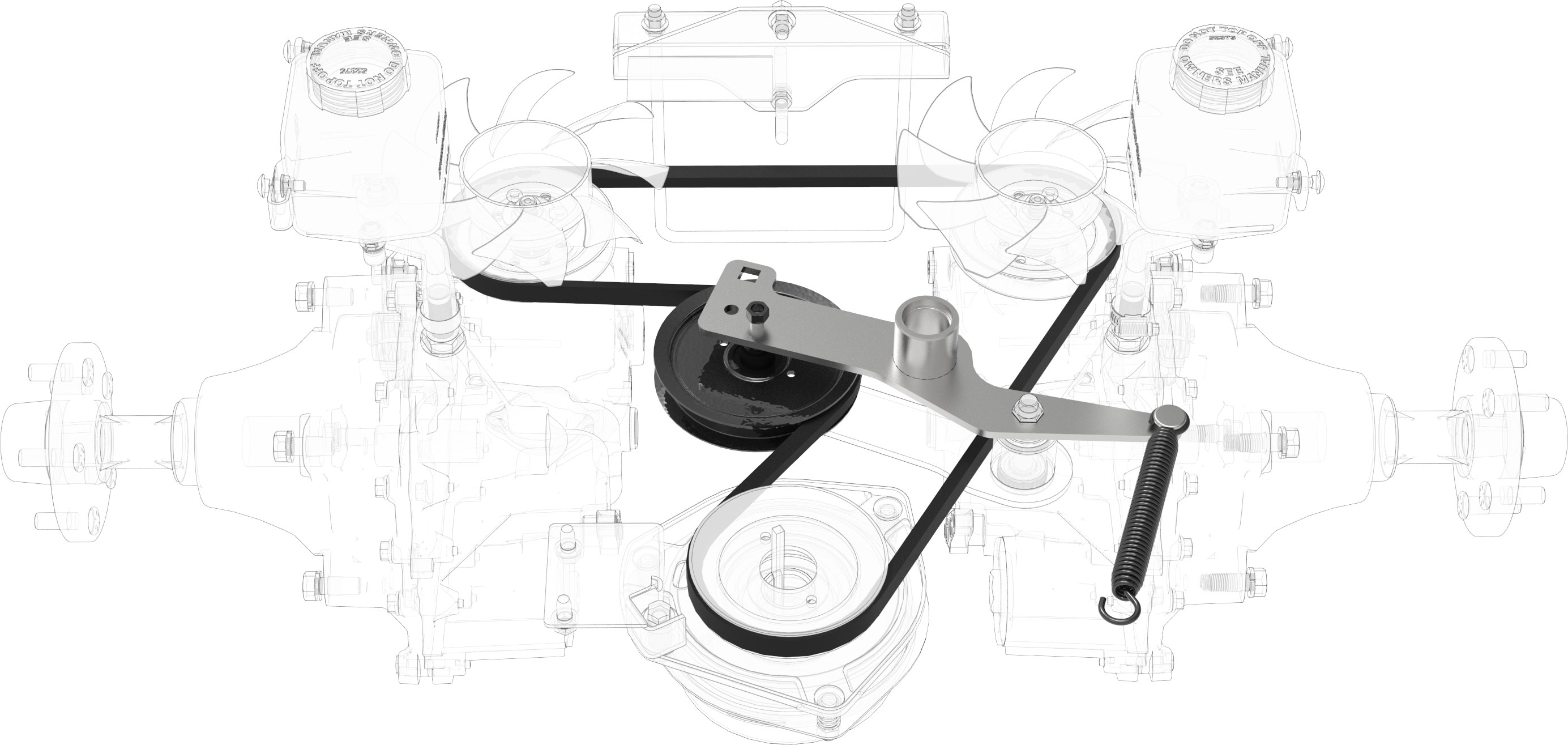

Idler Bracket and Idler Pulley

The Idler bracket and Idler Pulley will place tension onto the transmission drive belt with the idler spring in place. There

is a square hole in the end of the idler bracket that allows a technician to insert a 3/8" extension into to help

disengage the idler when the belt needs to be removed. The spring is non-adjustable.

-

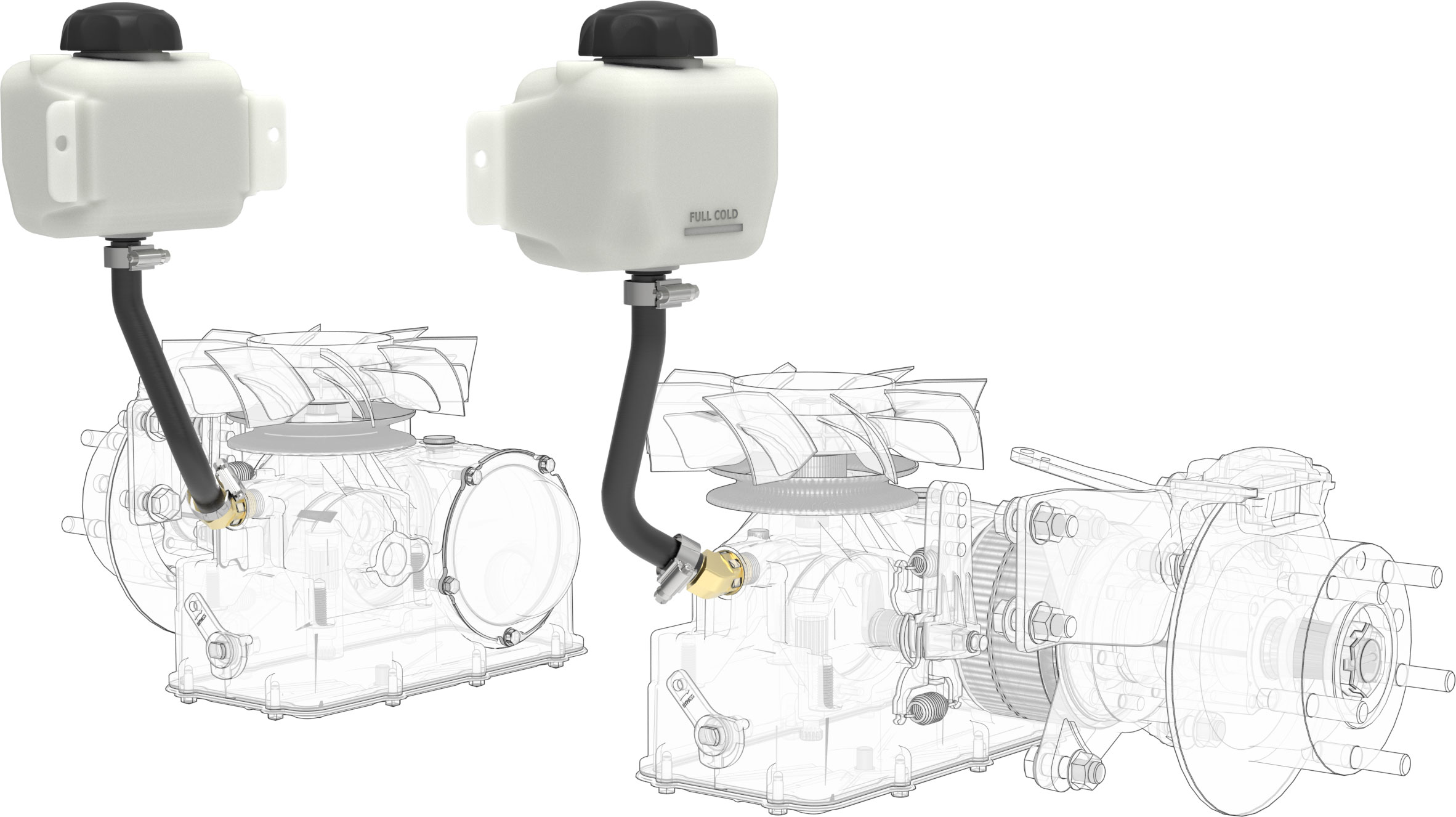

Expansion Tank

The HTJ expansion tank is integrated into the housing to allow for oil expansion during operation.

This also eliminates the need for remotely mounted plastic external expansion tanks.

-

Expansion Tank

The HTJ expansion tank is integrated into the housing to allow for oil expansion during operation.

This also eliminates the need for remotely mounted plastic external expansion tanks.

-

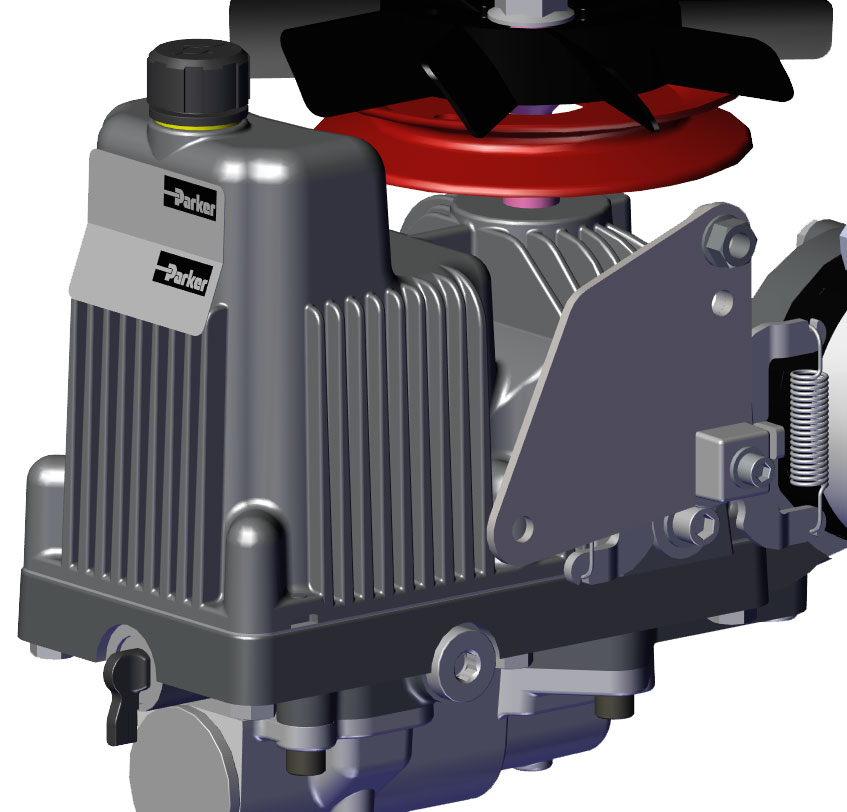

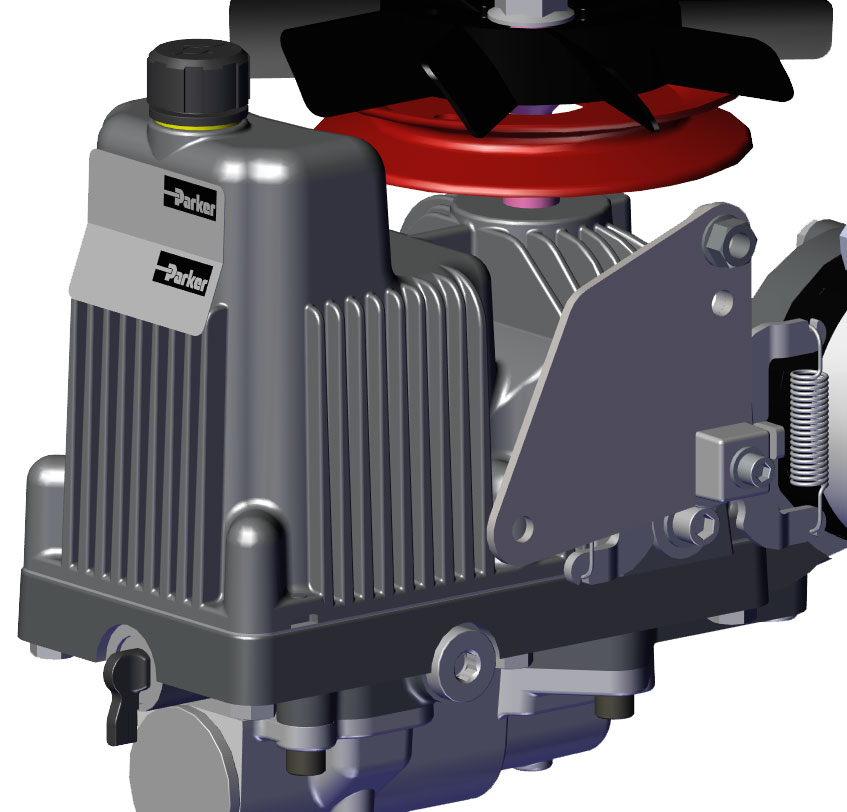

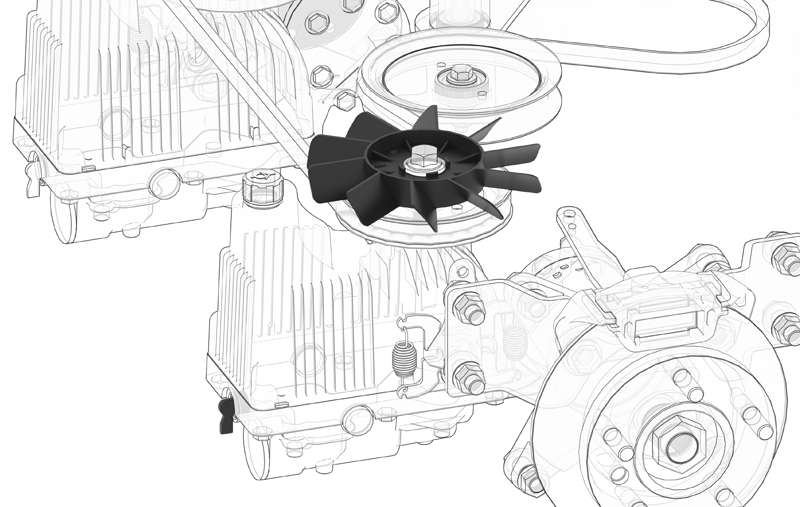

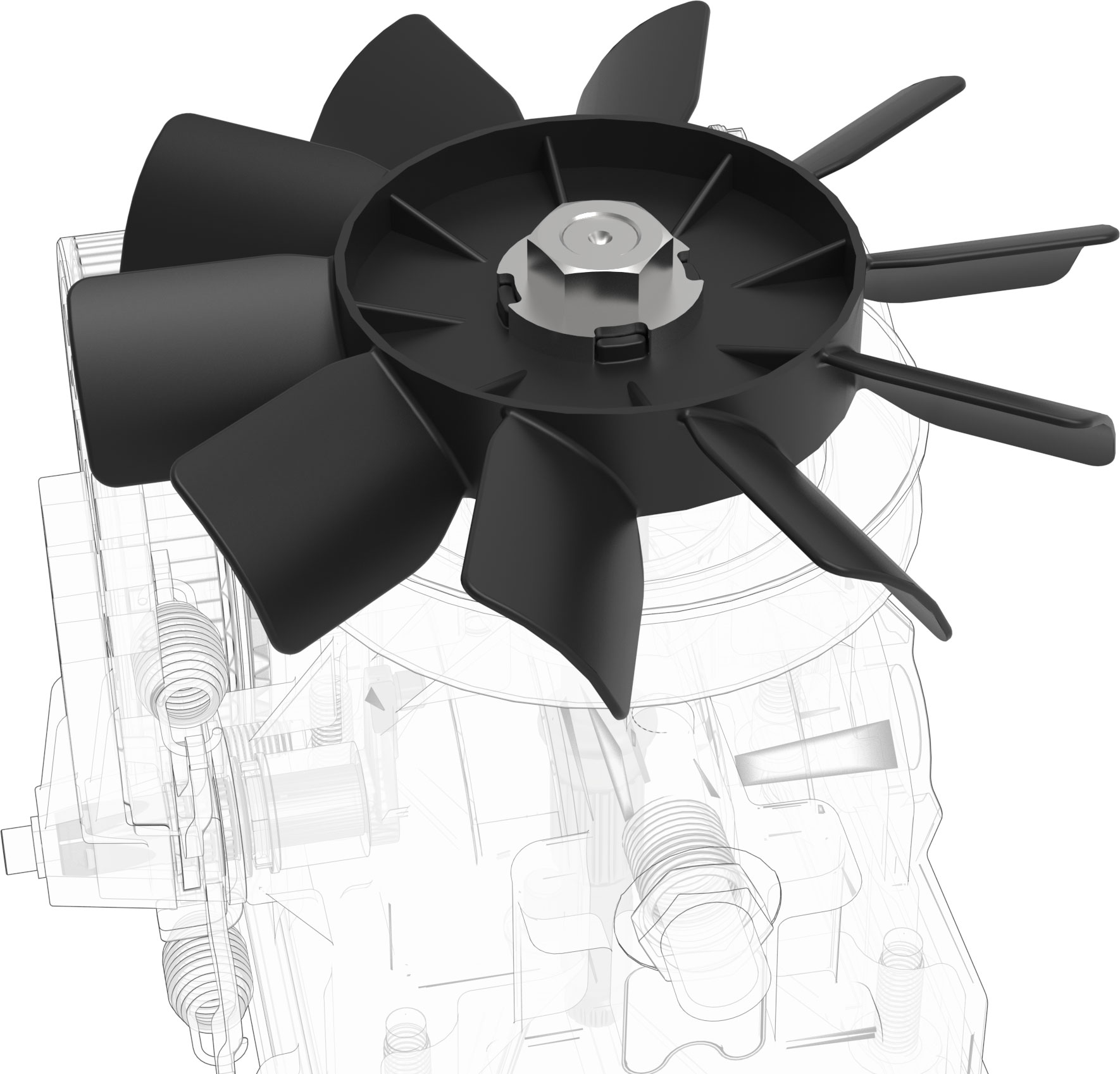

Fan Assembly

The fan assembly is mounted directly above the input pulley on the HTJ Transaxles and is designed to keep

the transaxle cool during operation. Each fan has 10 fins, which are critical for proper cooling. If

any fins are broken, the fan needs to be replaced.

The fan is held in place by a four-tabbed spacer and 5/8" nut, which has to be torqued to 55-70 ft.-lbs.

Parker has a service kit for the Fan Assembly: SK000275.

HTJ Service Manual

-

Fan Assembly

The fan assembly is mounted directly above the input pulley on the HTJ Transaxles and is designed to keep

the transaxle cool during operation. Each fan has 10 fins, which are critical for proper cooling. If

any fins are broken, the fan needs to be replaced.

The fan is held in place by a four-tabbed spacer and 5/8" nut, which has to be torqued to 55-70 ft.-lbs.

Parker has a service kit for the Fan Assembly: SK000275.

HTJ Service Manual

-

Breather / Dipstick

The HTJ transaxle has an easy-to-read dipstick that also functions as a breather for the transmission.

Take note the transmission oil should be checked when cold. Add approved transmission fluid to the full

range to ensure oil level is maintained.

-

Breather / Dipstick

The HTJ transaxle has an easy-to-read dipstick that also functions as a breather for the transmission.

Take note the transmission oil should be checked when cold. Add approved transmission fluid to the full

range to ensure oil level is maintained.

- Use the control bar or mouse to view the 360-degree image.

- Select the markers for information about each system.

-

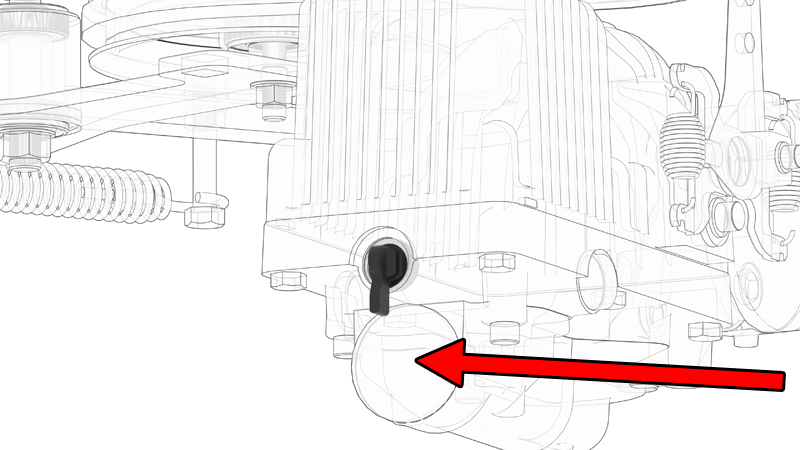

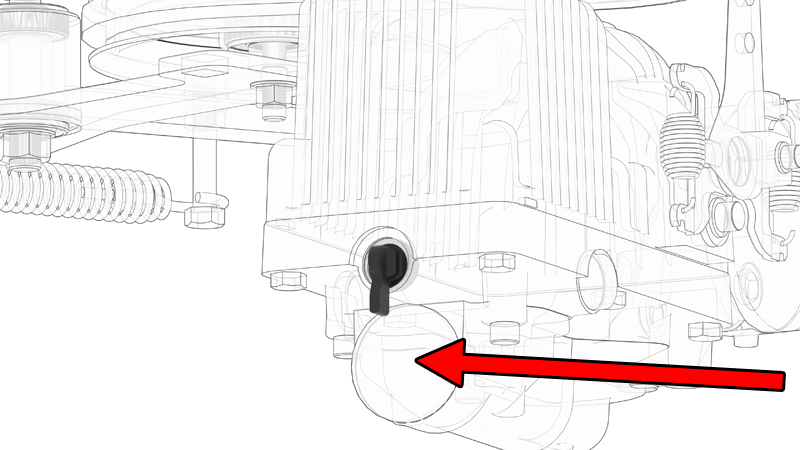

Dump Valve

Each Parker HTG hydrostatic transaxle has a dump valve, which is located on the front side of

the transaxle and is easily accessible in the front of each rear wheel. When the dump valve is released,

it will allow the operator to easily freewheel the Zero-Turn.

-

Filter

The oil filter is located on the rear side of the HTG hydrostatic transaxle and is easily accessible with

the unit installed in the Zero-Turn. The oil filter is expected to be replaced during each oil change.

The break-in oil period is at 300 hours and every 1,000 hours thereafter if Parker HT-1000™ Oil is used.

Oil filters will be available in the Oil Service Kit (70724100).

Further Information

-

Idler Bracket and Idler Pulley

The Idler bracket and Idler Pulley will place tension onto the transmission drive belt with the

idler spring in place. There is a square hole in the end of the idler bracket that allows a technician

to insert a 3/8" extension into to help disengage the idler when the belt needs to be removed.

The spring is non-adjustable.

-

Expansion Tank

Each HTG transaxle has a rubber hose and expansion tank to allow for oil expansion during operation.

During any oil change or service procedure to the transaxles, take note of the Cold Fill line on the

expansion tanks and ensure that the oil level is maintained to this line.

Please note: the expansion tanks are mounted to vertical brackets on the suspension pod. Upon removal

of the pod system, the two mounting bolts for each expansion tank will need to be removed. Take caution to ensure

that the expansion tanks are free and clear from the pod during removal and installation.

-

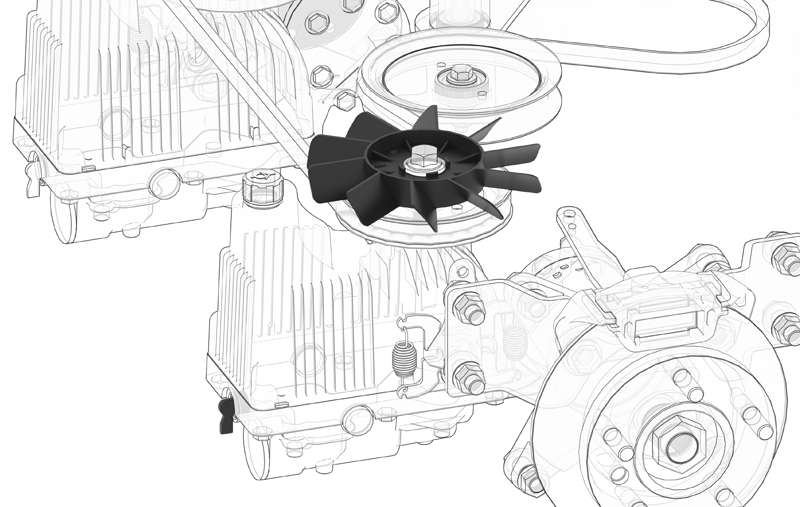

Fan Assembly

The fan assembly is mounted directly above the input pulley on the HTG Transaxles and is designed to keep the

transaxle cool during operation. Each fan has 10 fins, which are critical for proper cooling. If any fins are

broken, the fan needs to be replaced.

The fan is held in place by a four-tabbed spacer and 5/8" nut, which has to be torqued to 55-70 ft.-lbs.

Parker has a service kit for the Fan Assembly: SK000275.

HTG Service Manual